Environmental Protection

Environmental policy of Franken-Schotter GmbH & Co. KG

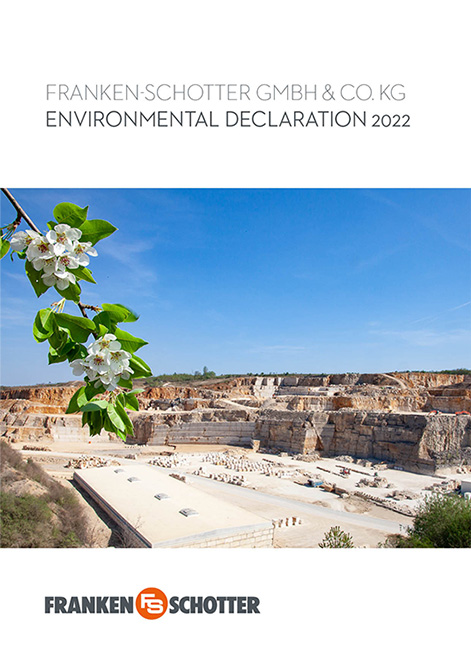

Franken-Schotter’s roots are as a natural resource processor. Although we have access to one of the largest natural stone reserves in the world, we do work with a non-renewable resource and therefore must ensure that these resources are available for future generations to come. With that in mind we have a sense of obligation to use our natural resources in an efficient and respectful manner and keep our environmental footprint to a minimum. This mentality is reflected all along our supply chain, from our quarrying activities all the way down to the production of our finished products. We operate on a zero waste basis, meaning that everything that we take from the earth is utilized.

Once we have finished quarrying stone the areas of extraction are re-naturalized, returning the area to its natural state, minimizing the effect on plants and wildlife as well as our communities.

By investing in new technologies and using sustainable quarrying practices and the use of chain saws we have been able to increase our natural stone yield up to 100% while using 75% less fuel. Dynamite consumption has also been reduced by a factor of four since 2007. With the use of a state of the art resin line we have been able to increase our yield another 20%. By focusing on our technologies we have been able to add value to our products and have been able to increase our revenue by 300% while simultaneously keeping the amount of stone we extract from our quarries at consistent levels.

We have implemented an environmental management system in order to continuously document and improve our advances and provide transparency to our environmental activities. We are proud to be EMAS III / ISO 14001 certified and have EPDs for our wall cladding and floorings products since 2015.

We have made great strides in our sustainability program over the years but resting on these laurels doesn’t fit into our business culture, therefore we plan to continually improve our processes in order to keep our environmental footprint to an absolute minimum.

Karl Tratz

Managing Director